How To Choose the Right Laser Cutting Machine For Sheet Metal?

Introduction Laser Cutting

Laser cutting machines are advanced equipment that cuts various substances, including metal, plastic, and wood. These machines use a high-powered laser beam that melts, burns, or vaporizes the material along a predetermined path. The result: correct cuts with minimal waste.

Ever wonder how producers make intricate designs on steel sheets? They do it with precision. Why are laser-cutting machines preferred in industries? They offer accuracy, deliver performance, excel in cutting operations, provide unparalleled precision, and ensure efficiency. Let’s discover the captivating world of laser-cutting machines and their secrets.

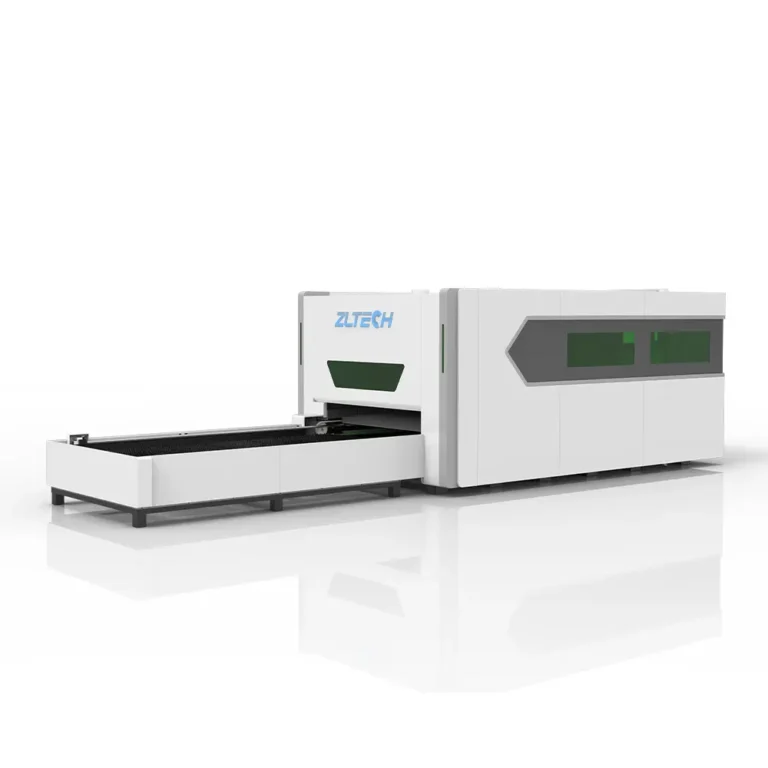

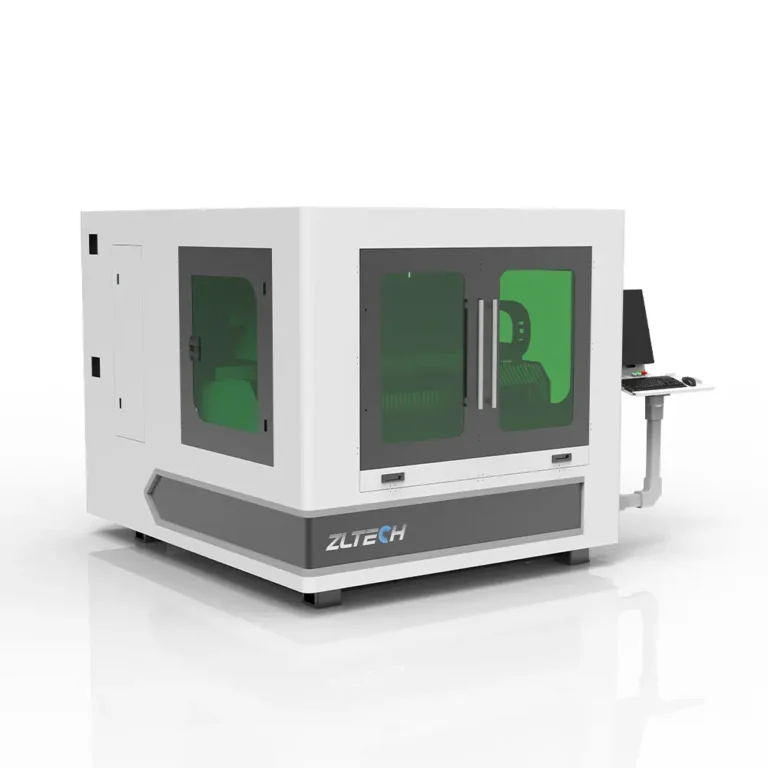

Laser-cutting machines for sheets offer unmatched precision and flexibility in material cutting. They are essential tools in manufacturing, automotive, aerospace, and signage. These machines use advanced laser technology. They cut through diverse materials. Their accuracy is outstanding. They can easily handle complex designs and intricate shapes, ensuring ease of production.

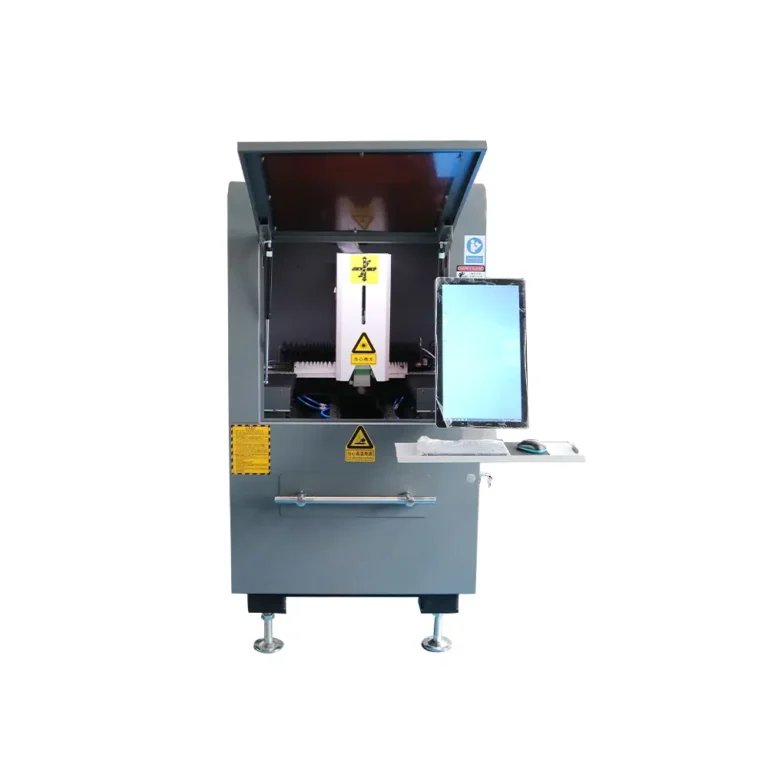

Types of laser cutting machines

Imagine a world where lasers are like magical scissors. They quickly cut through materials! There are different laser-cutting machines, each with special powers. It’s like having a superhero team with lasers that can cut through metal, wood, and fabric. With these incredible machines, we create, make beautiful things, and bring imagination to life.

Types of Sheet Metal!

Imagine sheet metal as a big box of colorful crayons – each type has its unique color! Like crayons, there are many types of sheet metal, each with unique qualities and uses. Some are shiny and smooth like a mirror, while others are rugged and tough like a superhero’s shield! With all these different types, we can build amazing things and bring our wildest ideas to life!

Laser Cutting Requirements and Capacity

Cutting requirements and ability are critical when deciding on a laser cutting system. Determine material thickness, size, and extent. Select a system with suitable slicing capabilities. Matching ability to necessities guarantees green operation. Assess wishes to avoid underperforming or overcapacity machines. The material thickness impacts the slicing ability. Thicker substances need better power and large mattress sizes. Size and extent decide to deal with ability. Check necessities to fulfill manufacturing needs effectively.

Laser Cutting Speed and Accuracy

Cutting speed and accuracy are like the heartbeat of crafting dreams. For a dancer to move, specific machines must cut fast. This precision is necessary to create wonders. It’s like a magical dance where every move is perfect and every step is in harmony. With the correct cutting speed and accuracy, our dreams can become reality. This process happens wonderfully.

Laser Cutting Space and Installation Requirements

When dreaming about space, we must think about where to put everything! Space and installation requirements are akin to puzzle pieces. They help us figure out where things belong, ensuring our dreams can come true. It’s like finding the perfect spot for your favorite toy in your room. With suitable space and installation requirements, we can make our dreams soar high—they’ll rise like rockets in the sky!

Cost Considerations

Thinking about costs is akin to counting the coins in our piggy banks. It’s something we do before buying something special. Cost considerations help us decide if our dreams fit our budget. It’s like choosing between different treats at the store. It’s like ensuring we have enough money to buy the ingredients for our favorite dessert. With careful cost considerations, we can make our dreams a reality—without breaking the bank!

FAQ’s

How do laser-cutting machines work?

Laser-cutting machines use a high-powered laser beam. Following a set path, the beam melts, burns, and evaporates the material, resulting in precise cuts with minimal waste.

What are the main types of laser-cutting machines?

The main types of laser cutting machines are CO2 lasers and fiber lasers. CO2 lasers create the beam with a fuel line. Fibre lasers use doped optical fibers. These fibers have rare-earth elements.

Which materials are suitable for laser cutting?

Laser-cutting machines are suitable for slicing many substances, including metal, plastic, and wood. Different styles of lasers are better suited for specific substances. CO2 lasers work best with thicker materials. Fibre lasers are better for thin metals. They’re also suitable for reflective substances.

Conclusion:

In conclusion, choosing the right laser-cutting system for sheet metal is meticulous. It involves considering many elements, ensuring optimal performance and efficiency. Understanding different types of laser-slicing machines, including CO2 lasers and fiber lasers, is crucial. This helps determine the best choice based on cutting needs and fabric types.

Additionally, it is crucial to consider sheet metal properties, including steel, aluminum, stainless steel, and copper. Such consideration ensures compatibility and optimal performance.

They were slicing speed matters, as does accuracy. Space is also important. Setup necessities are crucial. They all contribute to making informed decisions. Fee issues also play a significant role in the decision-making process. By comparing those elements in detail, companies can identify their particular needs. This helps them choose a laser-cutting system. It maximizes efficiency and provides superb results.2

Post Comment