Simulations have recently become an important aspect of the rapidly developing world of robotics. They help design, engineer, and investigate who needs to test their robots, improve their performance, and expand the boundaries of their imagination without incurring the risks and costs of conducting such tests in reality. Nevertheless, the vast variety of robot simulation software can make it hard for you to choose the right one. Fortunately for you, we have composed a detailed guide to supplying you with all the information necessary to navigate the complex market and make the right choice. Prepare to unlock the full potential of robotic simulations and take your projects to the next level!

1. Identify Your Simulation Needs

Are you developing industrial robots for the factory floor? Or are you working in the field of service robotics, developing human or household assistants, or healthcare aids? Are you a scientist, working on the latest algorithms for autonomous navigation or robotic manipulation? Each of these applications needs different things from your simulation software.

It is essential to specify your simulation needs clearly from the beginning in order to choose the appropriate resources and position yourself for success. Robust physics engines, precise modelling of factory machinery in addition to production line components, and the capacity to simulate intricate material handling scenarios are necessary for industrial robotics applications. In testing perception algorithms, sensor simulation—such as for vision as well as range-finding—may also be crucial. Rich environments that mimic human living spaces alongside include lifelike models of furniture, appliances, and common objects are frequently needed for service robotics.

2. Prioritize User-Friendliness and Ease of Use

Although robotic simulations rely on complex computations and sophisticated models, the software should not add to your frustration or waste valuable time. A straightforward user interface and intuitive conceptualization can significantly boost the quality of your working process. Additionally, make sure that adequate documentation and tutorials are available online and consider the possibility of a large and welcoming user community. Furthermore, the software you select should be compatible with all operating systems, especially those already available in your company.

When creating new robotic systems, time is of the essence, so you don’t want to waste it spending hours on a simulation that won’t work. Search for software with an intuitive, contemporary interface that makes common tasks simple to access. Setup as well as iteration can be sped up by using graphical tools for creating environments, and modifying robot models, along with configuring scenarios. Workflows can be further streamlined by using code auto-completion, intelligent defaults, and intuitive parameter naming.

3. Assess the Fidelity and Realism of Simulations

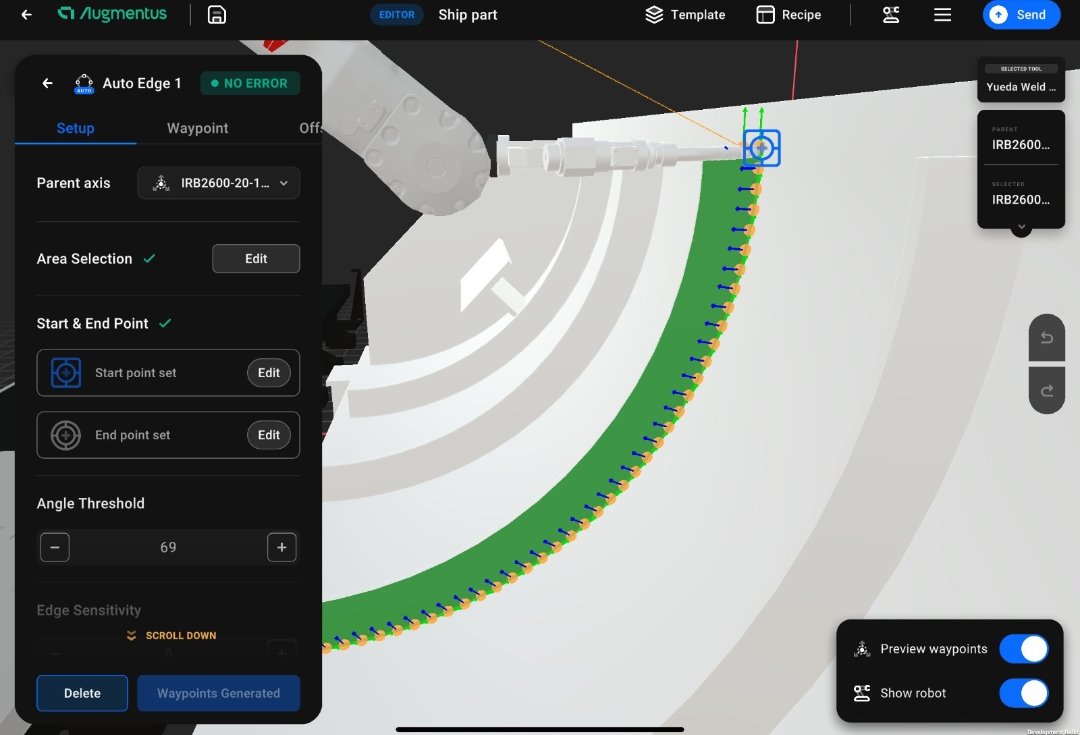

Investigate whether the simulation software adequately models complex environments: different terrains, interactions, impingements, and dynamic elements. Finally, you should pay attention to the accuracy of the physics engines, collision detection algorithms, and sensor simulations.

The ability to successfully translate virtual testing into real-world performance depends on realistic simulation fidelity. High-fidelity modelling of the physical characteristics as well as behaviours that are most important to you should be provided by the software. For instance, you would want extremely accurate terrain simulation with features like deformable surfaces, granular media, vegetation, and robustly modelled obstacles if you were building a search as well as rescue robot. Difficult inter-object constraints, collisions, along with friction models—which are essential for steep slopes or debris fields—should be handled by the physics engine.

4. Scalability and Performance

Finally, your simulation software should match your robotic projects’ level of complexity and evolve with them. The platform should be scalable and high-performing. A reliable software platform should perform large-scale simulations, allowing you to simulate complex scenarios consisting of multiple robots, intricate environments, and different sensor modalities.

Your simulation needs will scale with the sophistication of your robotics endeavours. A small proof-of-concept could eventually grow into a large industrial facility with a fleet of coordinated robots working there. A good simulation platform should be able to grow to accommodate this new level of complexity without becoming unusable. Cloud-based simulation features enable on-demand utilization of scalable computational resources. Workloads can be parallelized across multiple machines thanks to distributed simulation architectures.

5. Integration and Compatibility

When it comes to robotics, interoperability, and integration with other devices and software may make a huge difference. Your simulation software should interact fluidly with the programming languages, robot middleware, and development environments that you prefer to use. This will improve the flow and reduce the amount of time spent wrestling with disruptions.

Conclusion:

Ultimately, the right robot programming software is a decision that depends on your spare time and how much it would impact your simulation’s success. If you consider your need for tailoring, emphasis on user-friendliness, fidelity and realism, scalability and performance, and integration possibilities, you will be thoroughly prepared to step into this sea of possibilities. There is no such thing as a perfect simulation, only a tailored tool, customized to fit your needs and objectives.